Preclinic high-fidelity models are primarily designed based on real clinical imaging data such as CT/MRI. Using 3D printing technology and mold forming technology, silicone and gel are integrally molded to achieve realistic effects in both anatomical structure and operational texture.

If existing standard products cannot meet customer needs, Purin's team of experienced engineers can carry out customized product design and combine it with rapid mold technology to provide customers with convenient personalized product design and production services.

Made from human-grade silicone modified with Preclinic's unique formula and process, it offers a Shore hardness range from 0A to 40A, boasting a soft texture, strong durability, and a high degree of anatomical fidelity. Depending on the intended use, silicone with varying properties can be selected to simulate different surgical instrument operations, such as transport, shearing, suturing, and clamping. Storage and transportation are also convenient.

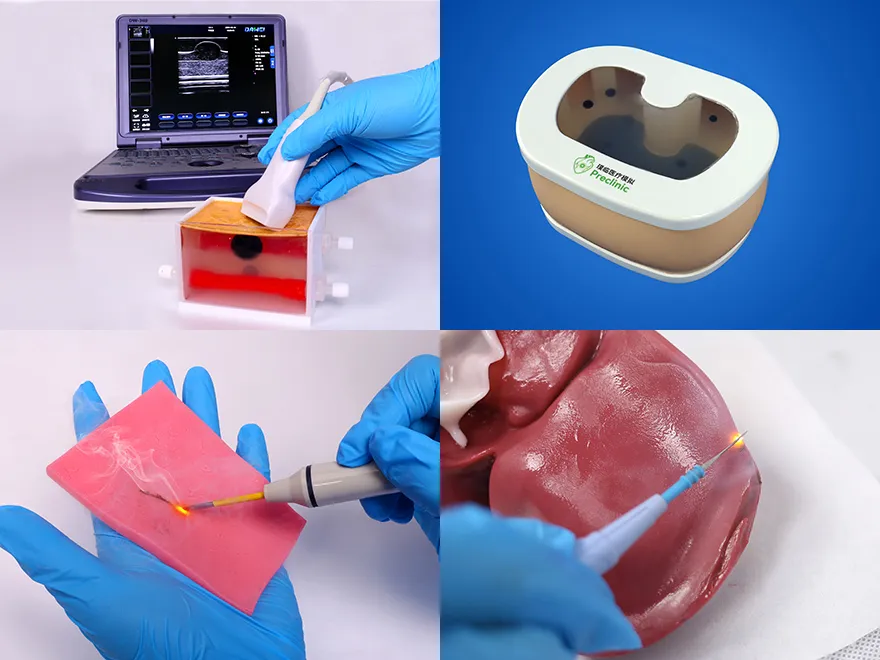

This gel material is specifically developed to simulate the electrical, acoustic, X-ray penetration, electron density, and cutting texture of human tissues and organs. It can be molded to resemble the morphology of various human tissues and organs, simulating imaging characteristics seen on CT, MRI, and ultrasound imaging devices, as well as the operation of energy-based devices such as electrosurgical units, ultrasonic scalpels, radiofrequency devices, and cryogenic devices. (Due to its high water content, this material requires sealed, refrigerated storage. Customers are advised to prepare a refrigerator for proper storage.)

It is specially developed to simulate human soft tissue and is used for simulating muscle, fat and other soft tissue palpation, puncture, X-ray projection, etc. It has a soft texture and will not fall off after repeated punctures. It is easy to store and transport.

Developed specifically for simulating human hard tissue, it is used for simulating the cutting, drilling, and nailing of various types of bones. Its moderate hardness allows it to simulate the shape and texture of both cortical and cancellous bone. It is easy to store and transport. Furthermore, it utilizes rapid mold production, which offers lower costs and shorter production cycles than traditional metal mold manufacturing processes, allowing for small-batch customization.

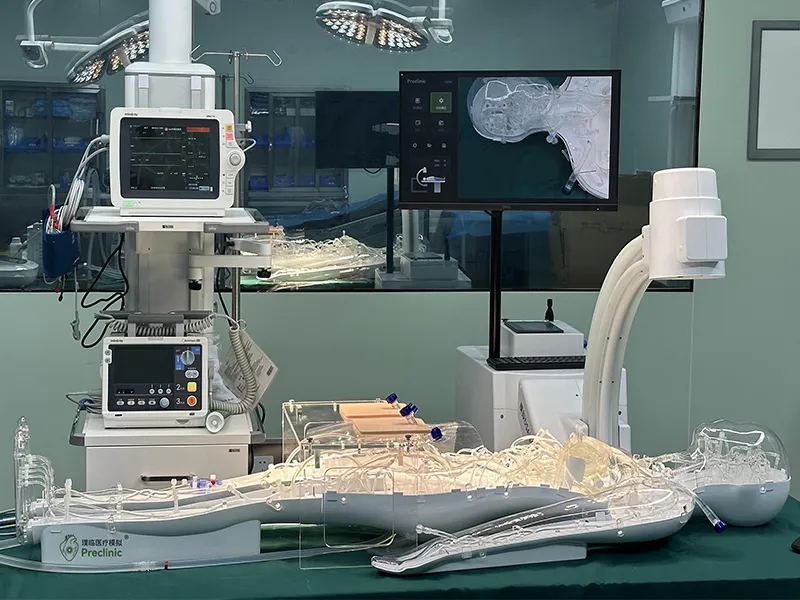

Used for simulation testing in the development of new surgical instruments and improvement of old products, it provides an operating and evaluation environment for the simulation of specific instruments by simulating the specific anatomical structure and physical characteristics of human tissues and organs.

Used for demonstration of medical devices, equipment and surgical procedures, it simulates the specific anatomical structure and operating texture of human tissues and organs to provide intuitive demonstration support for the operating procedures, operating principles and techniques of surgery or instruments.

It is used to provide new surgical learners with simulation operation support for specialized skills. They can practice repeatedly on the model to achieve the goal of mastering surgical operation procedures and operation techniques in a short period of time and improving surgical skills.